CappsNC NC-Fit Laser Example

The Goal

Accurate drilling & trimming on a very large composite part

The Challenge

Part is very large and non-rigid, taking a long time to setup.

The Solution

Leverage CAPPSNC & NCFIT with laser scanning and MPF Reposting

CappsNC NC-Fit Laser Example

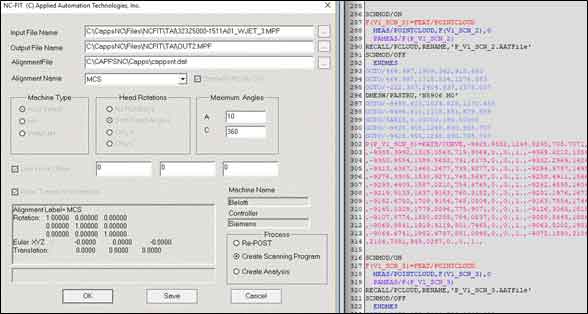

- Create a laser scanning measurement program

Scanning Program

Automatic program generation from a MPF program over the trimming path:

- Automatic head angles selection

- Full Program simulation

- Data point generation for analysis

- Part scanning measurement

Scan part trim lines- Convert scanning program into MPF

- Execute MPF program on machine

- Real time live feedback to load point cloud data

- Point Cloud rendering

Render point clouds onto surface- Use CAPPSNC Rendering option

- Convert point cloud into triangulated surfaces

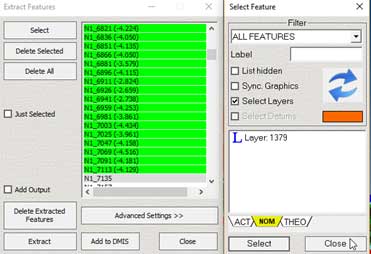

- Part shape analysis

Compare GCode data points to part shape- Use EXTRACT to analyze all G-Code data points to scan data

- Visualize data for a better understanding

- Re-post G-Code program

Repost newly generated program- Automatically convert original NC program by comparing each line with the part scan data

- Create new NC program by applying changes for 5 axis parameters to match the program to actual part Shape & Location