Mold & Die Applications

Mold making requires very careful cutting to avoid taking off too much material. With CappsNC closed loop feedback, a “Measure-Cut-Measure” approach can automatically be applied saving costly errors.

Closed loop measure-cut-measure is performed by CappsNC first measuring the part and then modifying and reposting the NC cutting program. This loop continues until the part is in tolerance, and requires very little need for operator intervention.

Tool wear is an inevitable part of machining. Through closed loop feedback, tool wear can be dynamically compensated based on measurement results.

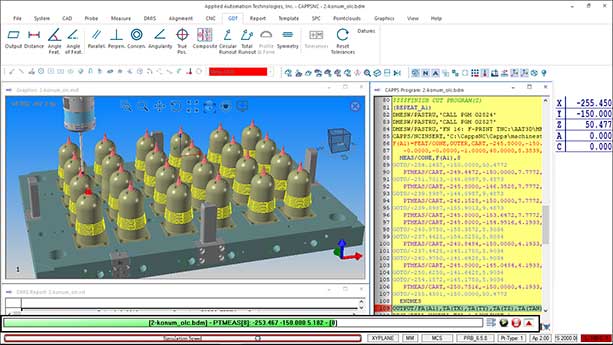

By making full use of the DMIS language, multi-cavity molds can loop a single cavity program as many times as required – all while maintaining closed loop feedback.