The Benefits & Features of CNC On-machine Probing

The Benefits & Features of CNC On-machine Probing.

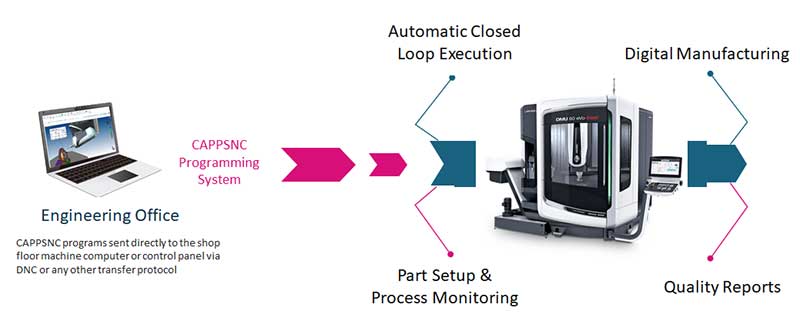

There are a lot of reasons why more and more people in the manufacturing sector are turning to on-machine probing. In-process metrology can verify the dimensions and alignment of the workpiece, making certain that the tool path is not thrown off when there are small differences in the workpiece alignment in the part setup. Touch probes are exceptional when confirming the precise size and location of the fixture or workpiece, and this is accomplished quicker than you can with manual measurements, and errors are reduced too.

Ensuring that the tooling is in the correct position is as critical as ensuring the accurate positioning of the workpiece. Very small errors in the tool offset can cause a machining pass to be completely thrown off, potentially scraping a workpiece, and exposing the machine tool or tooling to potential damage. Just in the same way that minor errors can be identified throughout the set-up of the workpiece, in-process touch probes can detect inconsistencies of tool settings or tool wear in an accurate manner so that expensive errors are avoided.

On-machine probing is an important step towards improving efficiency. By not having to remove the part from the CNC machine and take the part to the quality lab for measurement, multiple steps and time are saved. In many cases as soon as a part is removed from the CNC machine, it cannot be placed back in the exact location, so if the part is found to be incorrect in the metrology lab, the part may not be able to be saved. With on-machine probing, “cut-measure-cut” can be performed using the on-machine metrology tools and direct metrology feedback within CappsNC, avoiding scrap.

On-machine probing software is also beneficial in terms of enhancing process control. By measuring the workpiece as a process within your manufacturing flow, errors can be identified by the user through monitoring machined features. For instance, when working with a hard-to-machine material, tool deflection can result in a lower material removal rate than anticipated. Nevertheless, a touch probe can determine when the part is outside tolerance throughout the process so that you can either be alerted as the user or the machine can even adjust automatically so that the cutter compensates the issue that has been flagged.