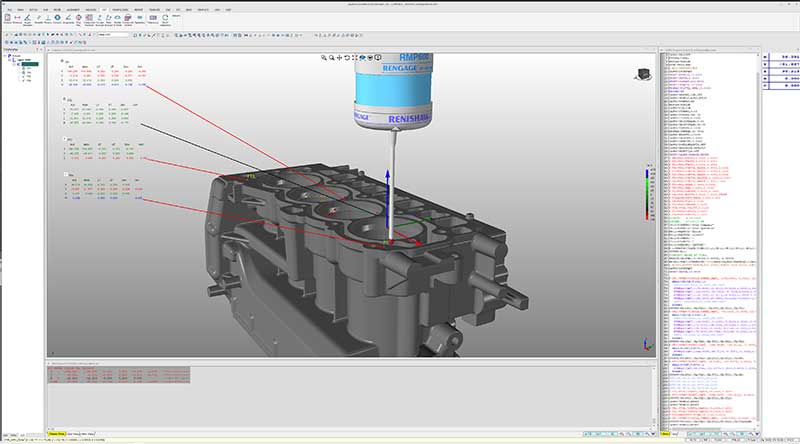

CappsNC CNC On-Machine Probing Software

On-Machine Probing

CappsNC CNC On-machine Probing Software is a metrology software that works on any machine tool to produce metrology information directly on the machine through on-machine probing and use this information to enable Smart Manufacturing and generate full CMM style measurement reports.

Multi-View graphics provides a graphical programming environment to make it very easy to create programs for any machine tool configuration.

Once the program is generated, CappsNC can connect with most machine tool controllers with a real time direct interface. A G-Code program is automatically created from the DMIS program so that the machine tool can be used to measure in the same manner as regular cutting programs by the operator or by an automation cycle.

A live 3D simulation of CNC on-machine probing is displayed in CappsNC graphics and calculations are performed as soon as data is collected.

The calculated metrology characteristics, such as best-fitting a data set to a CAD model, are used as a part of the on-the-fly decision making and written back to the machine tool controller as a part of the adaptive machining cycle.